Bonding substrates without an absorbent side with water-based adhesives requires a special procedure. To cure this type of adhesive the contained water must be eliminated (see drying time of aqueous systems). Particularly large-area bondings have an unfavourable ratio of adhesive joint to adhesive volume. We recommend the following procedure:

Pretreatment

1. Roughen the surface in the case of smooth substrates

2. Remove loose particles/dirt from the areas to be bonded

3. Degrease the surface with a suitable solvent Bonding

Bonding

4. Do not bond the whole surface, so that there are free spots in the bonding joint. This can be done in points or strips. (see video):

5. When joining the two sides of the substrate, the bonding gap should be chosen so that the ratio of bonding gap to bonding area is increased.

6. Optional drilling of air holes

Drying

7. Drying is accelerated by low humidity and high temperatures. The drying temperature should not exceed 70° C. Otherwise water vapour bubbles can form in the bonding joint, which can push the components apart and create pores in the adhesive joint, which impair the strength.

The setting of aqueous systems is based on the elimination of water. This happens due to evaporation or diffusion into the surrounding material, among other things. In the case of a coating or primer, evaporation over the entire surface is possible. Adhesives and sealants only lose their water through the glue gap or the joint and are therefore dependent on long drying times or on having an absorbent /diffusion-open substrate. The drying time of water-based systems depends on a large number of application and environmental conditions and must be determined for each application by preliminary tests.

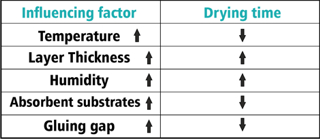

The following table shows the most important factors influencing the drying time:

Plastic dispersions provide a breeding ground for a large number of microorganisms. These produce unpleasant odours and can impair the product properties. For this reason, plastic dispersions are often protected by industrial preservatives. However, the preservative property is associated with possible skin sensitisation in humans. Thus, the dosage of the preservative is a compromise between occupational safety and effectiveness.

To ensure the shelf life of plastic dispersions, the introduction of foreign bodies into the product must be avoided. In particular food particles, coughing or sneezing lead to contamination of the material.

To ensure the shelf life of plastic dispersions, the introduction of foreign bodies into the product must be avoided. In particular food particles, coughing or sneezing lead to contamination of the material. When removing product from IBCs, it should be removed via the lower tap and not from above with a scoop. The upper IBC closure should be fully opened so that air can flow in, however the closure cap must be left loosely on the opening. If the use of a scoop from above is absolutely necessary, the device must be carefully disinfected beforehand.